Kee Track® Rigid Rail

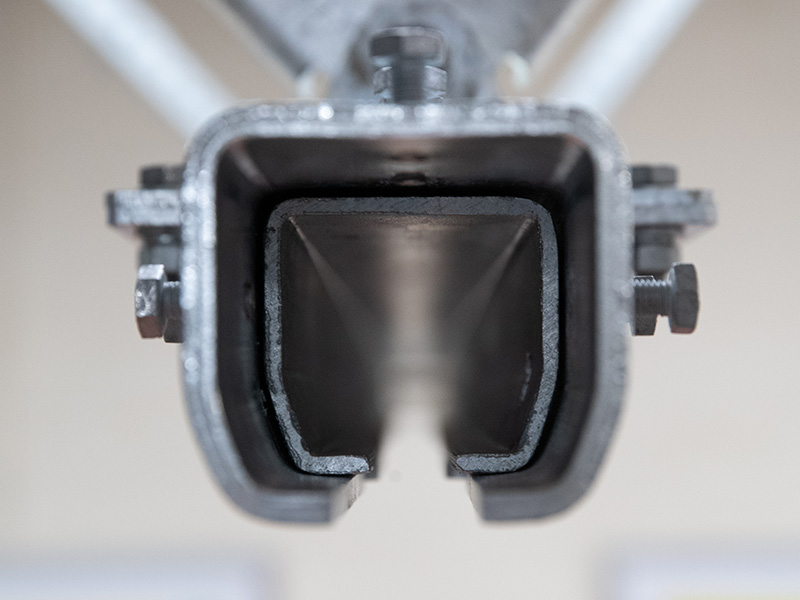

The Kee Track®, Fall Protection System, is a rigid rail overhead track system. The Kee Track® unique range of mounting options ensures secure installation for a wide variety of roofs. Kee Track® is ideal for working at short free-fall distances, such as carrying out maintenance on trains, trucks or aircraft with low ground clearance.

The Kee Track® Fall Protection System offers the safety of short fall arrest distances with the ease, economy and flexibility of modular installation. Additionally, the lightweight trolley with sealed bearings allows complete hands-free movement throughout the system.